-40%

USB CNC 6090 4axis 2200W ROUTER Engraver Cutting Machine For Metal Copper

$ 1208.61

- Description

- Size Guide

Description

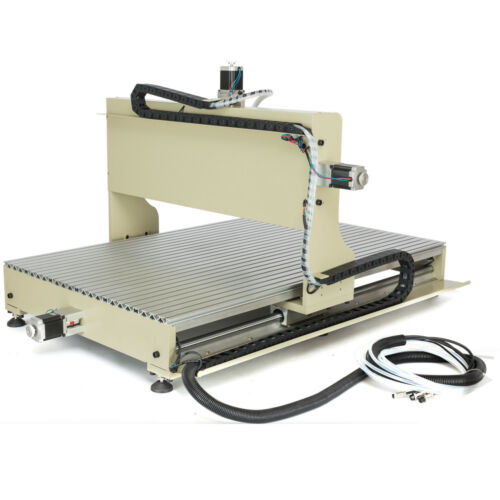

Package list:1X main unit (Frame)

1X main unit (working base)

2X Fence baffle

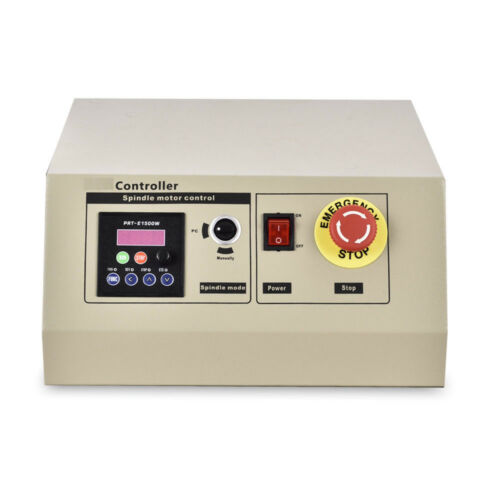

1X control box

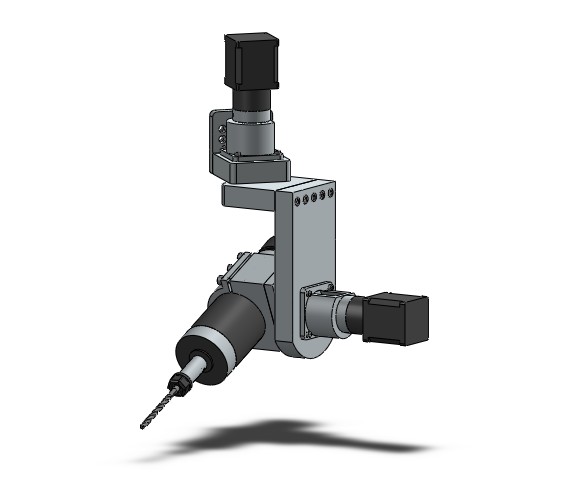

1X A axis

1X Sinal cable for A axis

1X pump

1X USB cable

2X cutter 2*6mm

2X cutter 3*6mm

10X 4*7mm round head

6X 4*10mm black Inner six angle screw with nut

8X 5*20mm black Inner six angle screw

4X 5*8mm Flat Philip's head screw with nut and gasket

8X 6*24mm BALCK FLAT Inner six angle screw

12X Aluminium fastener

1X 13-15# Wrench

1X 14-17# Wrench

2X six angle Wrench(3mm)

2X six angle Wrench(4mm)

1X Teflon tape

2X Fuse (5A)

1X Power cable

1X Manual

1x Tools Setting Auto-Check Instrument

Router engraving machine parameters:

Model:6090GZ

Outside dimension:1150x970x650mm(LxWxH)

Working platform size:1045x720mm(LxW)

How to use:

1.Assembling and locating the machine on steady desk well.

2.Make sure that your computer has a USB port output.

3. Place the control box in a ventilated dry place where there is no dust,no moisture

4.Connecting the control box with the machine and you computer and make sure the plug will not come off.

5.Correctly connect the machine with the controller. Don't suspended the cable which connect the Spindle motor with axis(X,Y,Z,A).Otherwise, It will

damage the driver of the controller.

6.Correctly install the Spindle motor and the heat pump. The heat pump should be covered completely in the water, then turned on the electric current to check whether the water-cooling system working well.

9. Before turn on the machine, please check all the cable and water- cooling system to make sure they are working fine.

10.You can enjoy making you dream with using our machine now.

Frame Material:The whole machine used 6061 aluminum profiles

Max. Feeding height:≤140mm(From base of Z axis to platform)

X,Y,Z Working Area:600x900x150mm

Sliding unit:

X axis:SFU1605 Ball Screws;

Y axis:SFU1605 Ball Screws;

Z axis:SFU1204 Ball Screws

Drive unit:

X axis:ø20 High intensity round rail,

Y axis: SBRø20 high-strength aluminum base rails;

Z axis: ø12 high-strength round rail

Stepping motor:two-phase 3A (with hand wheels)

Driving Power for Stepping motor:AC110,240W, Output DC24V10A

Maximum Idle speed:1500mm/m

Working Speed:50-1500mm/min (different material with different speed settings)

Spindle motor:2200W high-speed variable frequency spindle motor, ER20 chuck , matching 6mm bur

Variable-frequency Drive(VFD):AC110V, 2200W, 0-400Hz(built-in Control box )

(tips:1,The spindle motor must connect with the VFD.2,It cannot directly connect with the supply voltage (AC110V).3,Please don’t change the data setting of the VFD if you are not professional technicians, or it might damage the spindle motor.)

Drive of Stepping motor 0-3.5A adjustable four-axis drive(TB6560AHQchip, 24V power supply, 2,4,8,16Subdivision settings, Factory

setting:8subdivided)

Repositioning precision:≤0.05mm

Speed:0-24000r/m

Cooling method:Water cooling,Matching heat dissipation water pump

Spindle precision:Radial runout≤0.03mm

Carving command:G code/TAB file/nc/TAB /NCC/file

Protection:Emergency stop button

Communication interface:through USB PORT connect with computer

Input Volts: AC110V

Gross weight of machine :About 145kg/320lb

Update function: with limit switch

support system:

Support win7 64-bit and win10 64-bit installation

Application industry:

Woodworking industry: sculpture, round carving, wooden handicraft processing

Advertising signs: logo making, cutting acrylic , plastic molding, suit for making a variety of materials advertising decorative products

Other industries: The engraver could do shadow-carved, sculpture which widely used in the gift industry; can be used in aluminum cutting industry,such as aluminum, aluminum-plastic plate, aluminum honeycomb panels, aluminum, 3D engraving process, Artificial plate, cutting LED and neon letter , making plastic light box model; also can engrave on acrylic, copper, PVC board, artificial stone, MDF board, and other metal sheet.

Feature:

1,The NEW 2.2KW water-cooled VFD is available operating for long time,which can reinforced the processing ability of the machine and can be used to engrave on aluminum alloy and hard wood.

2,water cooling spindle works more stable and durable.

3, High quality accurate ball Screws drive make the engraving more precision.Anti-blackflash,high precision,long life circle.

Q1:I don't know how to setting parameters when need to use it .

Answer: We have instructions for our machine .All the parameters is very clearly on it. We also can provide online support service.

Q2:How can i do if the machine damage on the shipping way ?

Answer: No matter any problem with the machine please contact us by eBay message with photos or videos . We will give you a satisfied solution after check it.

Q3:How can i do when the machine have quality problem ?

Answer : Please take a video to show your problem to us .We have professional engineer to help you solve the problem.

On Dec-22-20 at 18:35:16 PST, seller added the following information:

On Jun-22-21 at 15:59:07 PDT, seller added the following information: