-40%

3-1/2" x 3 1/2" Hi Temperature Wood Stove Glass Replacement Made in the USA

$ 15.81

- Description

- Size Guide

Description

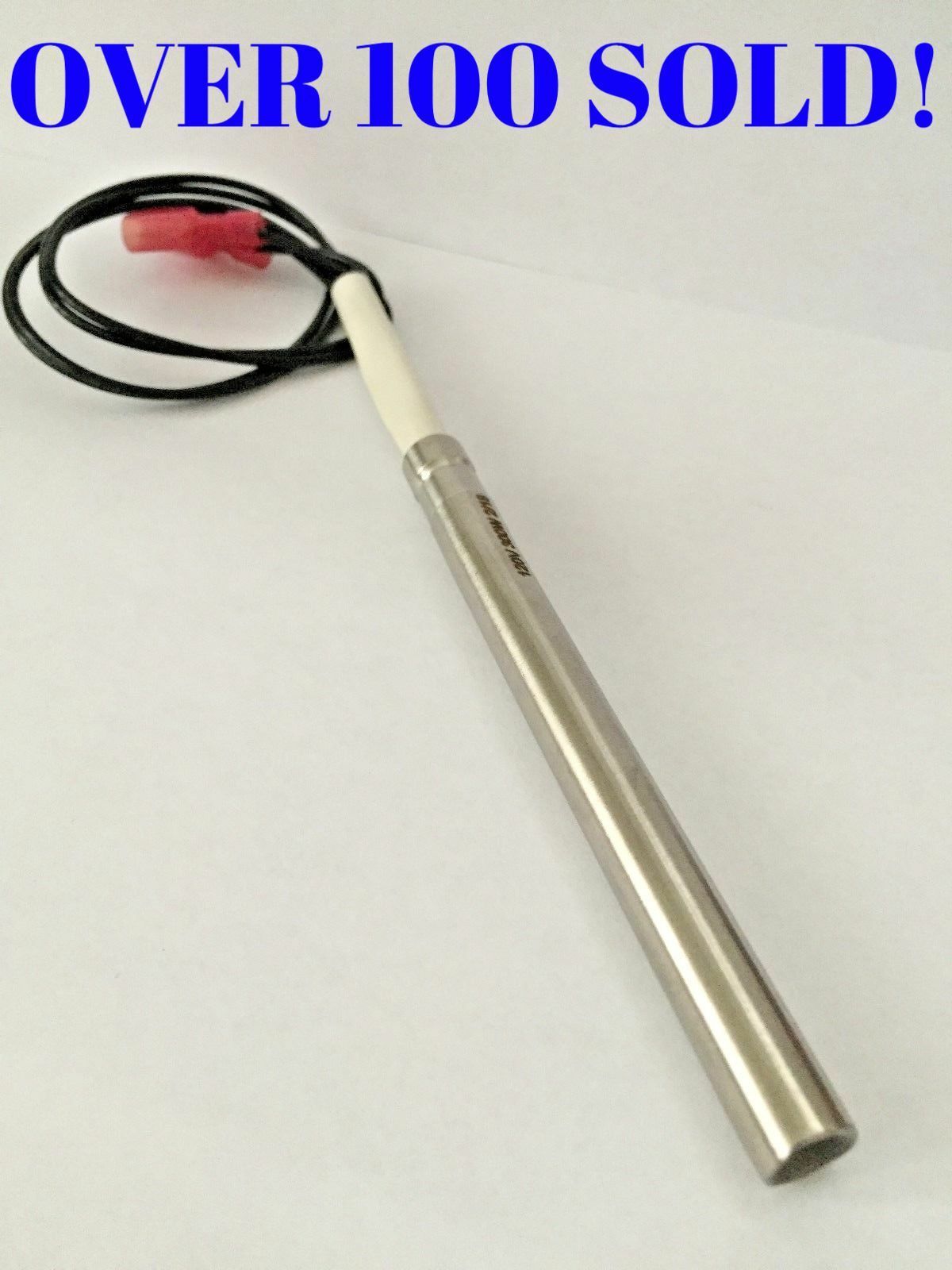

Product DescriptionYou are ordering a

3 1/2 x 3 1/2 (3/16)

inch

Thick piece of Wood Stove Replacement Glass. US made Pyroceram. (Corning)

If by chance you need a different size then message us and we will be happy to quote you.

"Wood Stove CERAMIC and Fireplace Insert Replacement Glass"

Pyroceram III wood stove glass is not ordinary glass. It is an amber transparent ceramic product. Pyroceram III has entirely different characteristics from tempered glass, as tempered glass goes through a heat process creating an outer shell surface of normal plate glass that can handle up to 550° with a thermal breakdown of 650. You cannot use tempered glass as a replacement for wood stove glass. The price of wood stove glass is much higher than tempered due to its features and the elements needed to produce the product. Pyroceram III has a high thermal ceramic with a heat rating of around 1450 degrees and is normally used in high heat applications such as wood stoves and fireplace inserts. Fireplace doors do not generate enough heat to exceed the thermal rating so if you need to replace your fireplace door, hi strength tempered glass is your best cost-effective option. However, there are new fireplace door inserts. These new products are inserted into your fireplace and act as a mini wood stove. They do create enough heat for the use of Pyroceram III. So if you need to replace the glass in your fireplace swing doors, and not a fireplace insert or a wood stove, then you need a tempered product.

Pyroceram III Ceramic glass breakage usually occurs as a result of impact or the retaining hardware was too tight or during eventual thermal breakdown which can take several years or even decades. When broken it will usually just crack like normal glass. Pyroceram III is amber in color and is made of 3/16 or 1/8th thick glass and is the best glass product to replace for your wood stove.

Many homes in the United States and worldwide are heated by burning wood or Peat as a fuel source for heating homes. Many of these furnaces are constructed by case iron or heat treated steel. However, there is always a glass product that provides a view of the flame in the burning chamber. This is not an ordinary glass product. Due to the extreme heat and pressure created inside the chamber, the glass needed has to withstand high heat conditions. In the last 20 years, the creation of the fireplace insert was introduced into residential homes.

The glass product suited for both the wood stove, and the fireplace insert is a product we sell is called

Pyroceram III. There are also several names given for each product and each one creates different temperature tolerances. they are the named neoprene robots etc. However, we carry the Pyroceram III product which is the product made in the USA license by Corning. our wood stove glass is of the highest quality in the market. Corning is the same company that created the product called Pyrex that we all use in our homes to cook food in. Pyrex was introduced in the 1940s as a fabulous substitute to cook your meatloaf and see how the meatloaf is doing being that the glass is transparent. prior to the introduction of Pyrex people use the cook with tin plates were Tin bowls where the meat or any other thing you are cooking would stick to the pan, and as we all know it is very difficult to clean Tin. the trade secret back in the 40s that made Pyrex indispensable and unique was the introduction of an element called Boron. Original Pyrex had a very low concentration of boron thus the heat rating for Pyrex is about the same as the maximum temperature the oven would produce. It also had a very high breakage rate due to the low concentration of boron making it glass and a low-level ceramic. Too many times I would make the same mistake as all of you where I took the meatloaf out of the Pyrex and then took the glass which was hot and put it in the sink and ran cold water on it only for it to break right before my eyes. That is not the case with wood stove glass. wood stove glass you literally can pour water on it while it is still hot and the glass will not break. This is due to the high concentration of boron which makes the glass less brittle and more ceramic in nature. It's almost like the product is transparent metal. The higher the boron concentration the higher the temperature rating glass can withstand.

During the process and manufacturing of wood stove glass, boron is added to float glass and rolled on tin sheets filled with water, which is commonly known as float glass, which gives the glass smooth transparent look like you have when you look outside your picture window at home. To make this glass less brittle, it undergoes another process called annealing. Which makes the glass less brittle and easy to cut. This is the reason why we can cut any size or any shape from a sheet of Pyroceram III wood stove glass. However, the higher concentration of boron that is introduced into the product does give it a slight amber color, being that boron is an amber colored element. But do not concern yourself with the transparency. Even though it is not clear you can still see through this glass clearly and once installed in the wood stove or fireplace insert new really don't know the difference. It does not take away from the ambiance of the flame which is the main reason why we have glass in fireplace inserts so people have the best of both worlds. One is your living room efficiently by burning the wood, pellets, or if you still old fashion Peate.

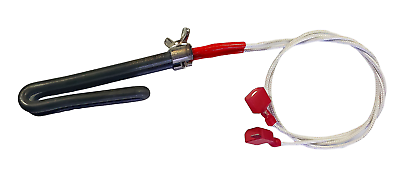

The life expectancy of wood stove glass is approximately 20 to 25 years. The major reason for breakage of wood stove glass is overfilling the chamber with wood, and it is disturbing that when you fill your wood stove, or fireplace insert before going to bed, only to wake up and see a crack is usually due to a rolling log that hit the glass. To help this wood stove glass and breaking when this happens is the use of a high-temperature fiberglass rope which sometimes will help in absorbing the shock. Check with your manufacturer's booklet if you still have it about the use of this would stove fiberglass rope. It is prudent that this rope is used to separate itself from any metal that is in a frame that surrounds the glass. Although there are many different applications of wood stove glass that are attached to either the wood stove with a fireplace insert is always smart to try to put a wood stove rope around the glass and the metal frame which keeps it in place. If you are replacing this glass because of age and the loss of clarity is crucial that you replace the glass with a new rope. Another reason for the high breakage rate of wood stove glass in the marketplace today is the manufacturers have replaced true wood stove glass with a substandard product called borosilicate. You will know the difference if you see the glass in the doors to be clear rather than Amber. I have been to the two largest hardware chains that sell wood stoves and wood stove inserts which I will not mention a year and seen these wood stove products with the clear glass in it. We have sold many pieces of glass to very unhappy customers after the first or second burn with the glass is broken for no reason. when the customer calls the manufacturer or the retailer many times they get the answer well it was your fault a lot must've hit the glass. They know the problem but again if you go to a reputable store that sells wood stoves and fireplaces inserts you will notice the amber color and the glass. However, you will spend more than 00 for anything of quality. Instead of getting painted high-speed steel expect to see cast-iron or other high-quality material. Remember when buying a brand-new wood stove or wood stove insert they are a lifetime investment something that you do not want to cut corners on. At full burn, the atmospheric temperature inside your wood stove or fireplace insert reaches as high as 1100°. Our product can handle this very easily, the clear borosilicate can only handle up to 800°. It was a cost-saving measure as some of these items are sold for less than 00 and the manufacturer had to cut costs in some way. So if you would just using one or two logs you can get away for a while but if you burn a lot and reach the 1100° atmospheric temperature that is normal in the unit this glass will reach its critical thermal breakdown which is around 900°. Our product easily handles up to 1450° with a thermal breakdown of 1650°. The other reason for replacement of wood stove glass is that over time the glass will go under a thing called atomization. This is the pitting and the discoloration of the glass over a long period of time. Like I said wood stove glass could last a very long time but eventually everything does have its point of no return.

Anytime you replace the wood stove glass from the door, it is always smart to take the door off the hinge, and laying it on a flat surface. Yes I know sometimes the handle gets in the way, and yes the screws sometimes are difficult to remove due to the age and the constant heat bombardment, but it is much easier to work on your head on a table. If you have difficulty in removing the screws we must remember that they have suspension and contraction capabilities just like the frame around itself. Both also might need to be replaced. All of these materials, the rope, the screws, the possibly bent frame, can all be found in any local retail location that sells wood stoves and fireplace inserts for a living. Just like any glass product, there is no uniform or consistent size of the glass nor is there anyone way of installing or removing this product. So you must use common sense sometimes. If the screw is hard to remove from the frame, first try to use a liquid wrench type product and let it soak. The other and quicker way is to apply high heat using a propane torch on the screw which usually will expand and become easier to remove. These screws are made for high temperature. Do not try to substitute them with low-grade stainless steel as they will not hold up with the heat stress. Also when surrounding the rope around the framed metal remember to always just hand tightened the screw. Too many people think we have to make it tighter so the glass will fall out this is not the case on the installation of the wood stove glass. This is why it is imperative to use the wood stove rope so the glass will not snap. It is always smart to screw this in a counterclockwise and tighten slowly as you go around.

Feel free to write to us if you ever have any questions. Also when measuring the glass prior to ordering, it is always best to remove the glass from the frame. The best measurement is from the glass it's in it now unless you had problems with this glass due to previous replacement. Unlike tempered glass, you can cut wood stove glass. If you have to cut anything less than a half an inch, Glass Shop's using wet carbide belt sanders have the ability to shorten this product. If you need to do this do a search in your local area plate glass and mirror shops as many of them will always have a standup wet carbide belt Sander. No respectable plate and glass company could ever run successfully without one.

I hope you have learned more about woodstove glass than you ever have before reading this article.

I would love to earn your business.